Welding Procedures and Type IV Cracking Tendency - an Experimental Study

J. A. Francis, W. Mazur and H. K. D. H. Bhadeshia

Abstract

Type IV cracking refers to the premature failure of a welded joint due to an enhanced rate of creep void formation in the fine-grained or inter-critically annealed heat-affected zone. Although a great deal of research effort has been directed at understanding the underlying mechanisms for this type of failure, most researchers have approached the problem from a metallurgical point of view.

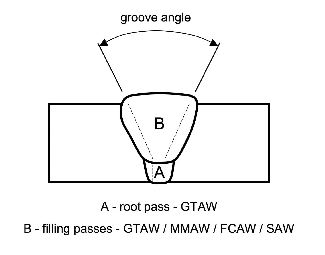

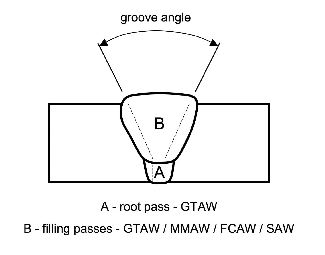

Comparatively little effort has been directed at understanding the effects of welding variables. In an earlier study the authors used neural networks in a Bayesian framework to make the first predictions for the effects of different welding variables on the tendency for type IV failure in 9-12 Cr steels. In the current work, the results of an experimental study on the effects of weld heat input, preheat temperature and groove angle are reported for P91 steel, and discussed in the context of earlier predictions.

3rd International Conference on Integrity of High Temperature Welds, 24-26 April 2007, pp.399-408, IOM Communications Ltd., London, ISBN 1-86125-166-1.

Download PDF file of paper.

Download slide presentation.

Type IV cracking study. Electrical heating blankets to maintain pre-heat temperature in the vicinity of the weld. |

Type IV cracking study - completed welds. |

Type IV cracking study. Preparation of weld. |

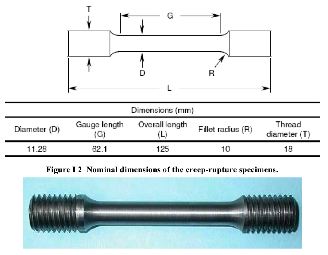

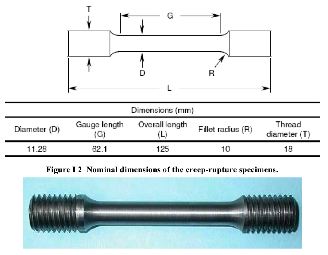

Type IV cracking study - the creep rupture test sample. |

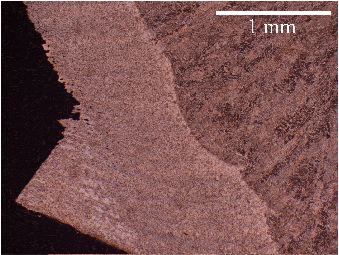

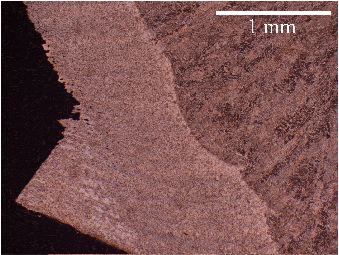

Type IV cracking study - typical rupture surface. |

Related Papers

Review on Type IV cracking in steel welds.

Quantitative Estimation of Type IV cracking Tendency.

Welding procedures and Type IV cracking.

Design of Alloys for The Energy Industries

Photographs of Australia, where this work was carried out.

Tempered martensite Fe-9Cr-1Mo weld metal.