The composition of the 50 mm wall thickness P91 steel pipe section, measured by optical emission spectroscopy and inductively-coupled plasma is:

0.10 C, 0.05 N, B < 0.0005, 0.29 Si, 0.4 Mn, 0.01 P, 0.01 S, 8.5 Cr, 0.9 Mo, 0.12 Ni, 0.01 Al, 0.2 V, 0.13 Cu, 0.07 Nb wt percent

The steel was supplied in the normalised and tempered condition.

Weld heat input either 0.8, 1.6 or 2.4 kJ/mm, as indicated in the captions.

The welding process for the filling passes was

flux-cored arc welding with a matching filler wire measuring 1.2 mm in

diameter. We used a single Vee joint preparation having an included angle

of 30°.

geometry

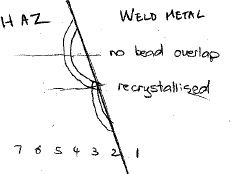

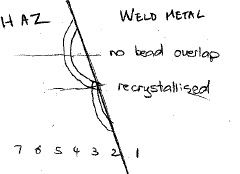

Schematic illustration of the positions where the photographs below were taken. The HAZ is the heat-affected zone.

|

Montage of weld

0.8 kJ/mm heat input. Montage with weld metal on the right and heat-affected zone on the left. The photographs are taken along a horizontal traverse which does not include any weld-bead overlap, as illustrated in the schematic drawing. Higher magnification snapshots follow.

|

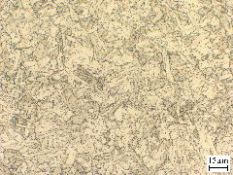

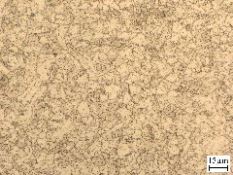

Martensite, HAZ

0.8 kJ/mm heat input. The photograph was taken at position 6 in the heat affected zone (HAZ), along a horizontal traverse which does not include any weld-bead overlap, as illustrated in the schematic drawing.

|

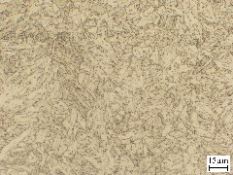

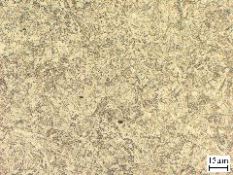

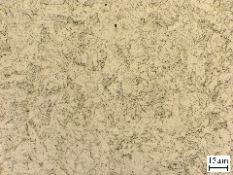

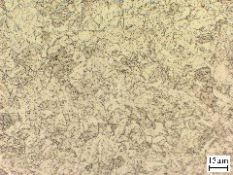

Martensite, HAZ

0.8 kJ/mm heat input. The photograph was taken at position 5 in the heat affected zone (HAZ), along a horizontal traverse which does not include any weld-bead overlap, as illustrated in the schematic drawing.

|

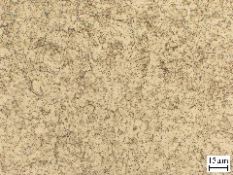

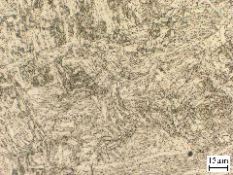

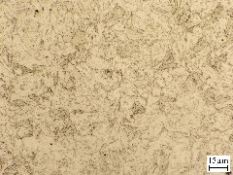

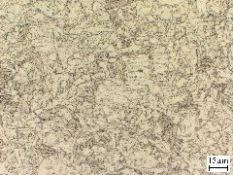

Martensite, HAZ

0.8 kJ/mm heat input. The photograph was taken at position 4 in the heat affected zone (HAZ), along a horizontal traverse which does not include any weld-bead overlap, as illustrated in the schematic drawing.

|

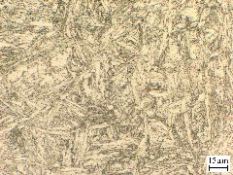

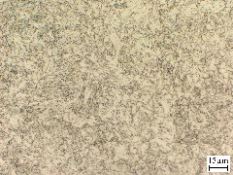

Martensite, HAZ

0.8 kJ/mm heat input. The photograph was taken at position 3 in the heat affected zone (HAZ), along a horizontal traverse which does not include any weld-bead overlap, as illustrated in the schematic drawing.

|

Martensite, HAZ

0.8 kJ/mm heat input. The photograph was taken at position 2 in the heat affected zone (HAZ), along a horizontal traverse which does not include any weld-bead overlap, as illustrated in the schematic drawing.

|

Martensite, weld metal

0.8 kJ/mm heat input. The photograph was taken at position 1 in the weld metal, along a horizontal traverse which does not include any weld-bead overlap, as illustrated in the schematic drawing.

|

Montage of weld

0.8 kJ/mm heat input. Montage with weld metal on the right and heat-affected zone on the left. The photographs are taken along a horizontal traverse which covers the 'recrystallised' region where weld-beads overlap, as illustrated in the schematic drawing. Higher magnification snapshots follow.

|

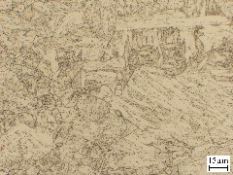

Martensite HAZ

0.8 kJ/mm heat input. Montage with weld metal on the right and heat-affected zone on the left. The photograph was taken at position 6 of the HAZ, along a horizontal traverse which covers the 'recrystallised' region where weld-beads overlap, as illustrated in the schematic drawing.

|

Martensite, HAZ

0.8 kJ/mm heat input. Montage with weld metal on the right and heat-affected zone on the left. The photograph was taken at position 5 of the HAZ, along a horizontal traverse which covers the 'recrystallised' region where weld-beads overlap, as illustrated in the schematic drawing.

|

Martensite, HAZ

0.8 kJ/mm heat input. Montage with weld metal on the right and heat-affected zone on the left. The photograph was taken at position 4 of the HAZ, along a horizontal traverse which covers the 'recrystallised' region where weld-beads overlap, as illustrated in the schematic drawing.

|

Martensite, HAZ

0.8 kJ/mm heat input. Montage with weld metal on the right and heat-affected zone on the left. The photograph was taken at position 3 of the HAZ, along a horizontal traverse which covers the 'recrystallised' region where weld-beads overlap, as illustrated in the schematic drawing.

|

Martensite, weld metal

0.8 kJ/mm heat input. Montage with weld metal on the right and heat-affected zone on the left. The photograph was taken at position 2 of the weld metal, along a horizontal traverse which covers the 'recrystallised' region where weld-beads overlap, as illustrated in the schematic drawing.

|

Martensite, weld metal

0.8 kJ/mm heat input. Montage with weld metal on the right and heat-affected zone on the left. The photograph was taken at position 1 of the weld metal, along a horizontal traverse which covers the 'recrystallised' region where weld-beads overlap, as illustrated in the schematic drawing.

|

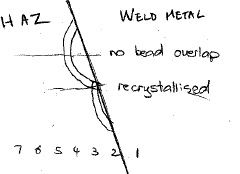

geometry

Schematic illustration of the positions where the photographs below were taken. The HAZ is the heat-affected zone.

|

Montage of Weld

01.6 kJ/mm heat input. Montage with weld metal on the right and heat-affected zone on the left. The photographs are taken along a horizontal traverse which does not include any weld-bead overlap, as illustrated in the schematic drawing. Higher magnification snapshots follow.

|

Martensite, HAZ

1.6 kJ/mm heat input. The photograph was taken at position 7 in the heat affected zone (HAZ), along a horizontal traverse which does not include any weld-bead overlap, as illustrated in the schematic drawing.

|

Martensite, HAZ

1.6 kJ/mm heat input. The photograph was taken at position 6 in the heat affected zone (HAZ), along a horizontal traverse which does not include any weld-bead overlap, as illustrated in the schematic drawing.

|

Martensite, HAZ

1.6 kJ/mm heat input. The photograph was taken at position 5 in the heat affected zone (HAZ), along a horizontal traverse which does not include any weld-bead overlap, as illustrated in the schematic drawing.

|

Martensite, HAZ

1.6 kJ/mm heat input. The photograph was taken at position 4 in the heat affected zone (HAZ), along a horizontal traverse which does not include any weld-bead overlap, as illustrated in the schematic drawing.

|

Martensite, HAZ

1.6 kJ/mm heat input. The photograph was taken at position 3 in the heat affected zone (HAZ), along a horizontal traverse which does not include any weld-bead overlap, as illustrated in the schematic drawing.

|

Martensite, HAZ

1.6 kJ/mm heat input. The photograph was taken at position 2 in the heat affected zone (HAZ), along a horizontal traverse which does not include any weld-bead overlap, as illustrated in the schematic drawing.

|

Martensite, weld metal

1.6 kJ/mm heat input. The photograph was taken at position 1 in the weld metal, along a horizontal traverse which does not include any weld-bead overlap, as illustrated in the schematic drawing.

|

Montage of weld

1.6 kJ/mm heat input. Montage with weld metal on the right and heat-affected zone on the left. The photographs are taken along a horizontal traverse which covers the 'recrystallised' region where weld-beads overlap, as illustrated in the schematic drawing. Higher magnification snapshots follow.

|

Martensite, HAZ

1.6 kJ/mm heat input. Montage with weld metal on the right and heat-affected zone on the left. The photograph was taken at position 7 of the HAZ, along a horizontal traverse which covers the 'recrystallised' region where weld-beads overlap, as illustrated in the schematic drawing.

|

Martensite, HAZ

1.6 kJ/mm heat input. Montage with weld metal on the right and heat-affected zone on the left. The photograph was taken at position 6 of the HAZ, along a horizontal traverse which covers the 'recrystallised' region where weld-beads overlap, as illustrated in the schematic drawing.

|

Martensite, HAZ

1.6 kJ/mm heat input. Montage with weld metal on the right and heat-affected zone on the left. The photograph was taken at position 5 of the HAZ, along a horizontal traverse which covers the 'recrystallised' region where weld-beads overlap, as illustrated in the schematic drawing.

|

Martensite, HAZ

1.6 kJ/mm heat input. Montage with weld metal on the right and heat-affected zone on the left. The photograph was taken at position 4 of the HAZ, along a horizontal traverse which covers the 'recrystallised' region where weld-beads overlap, as illustrated in the schematic drawing.

|

Martensite, HAZ

1.6 kJ/mm heat input. Montage with weld metal on the right and heat-affected zone on the left. The photograph was taken at position 3 of the HAZ, along a horizontal traverse which covers the 'recrystallised' region where weld-beads overlap, as illustrated in the schematic drawing.

|

Martensite, weld metal

1.6 kJ/mm heat input. Montage with weld metal on the right and heat-affected zone on the left. The photograph was taken at position 2 of the weld metal, along a horizontal traverse which covers the 'recrystallised' region where weld-beads overlap, as illustrated in the schematic drawing.

|

Martensite, weld metal

1.6 kJ/mm heat input. Montage with weld metal on the right and heat-affected zone on the left. The photograph was taken at position 1 of the weld metal, along a horizontal traverse which covers the 'recrystallised' region where weld-beads overlap, as illustrated in the schematic drawing.

|

geometry

Schematic illustration of the positions where the photographs below were taken. The HAZ is the heat-affected zone.

|

Montage of weld

2.4 kJ/mm heat input. Montage with weld metal on the right and heat-affected zone on the left. The photographs are taken along a horizontal traverse which does not include any weld-bead overlap, as illustrated in the schematic drawing. Higher magnification snapshots follow.

|

Martensite, HAZ

2.4 kJ/mm heat input. The photograph was taken at position 8 in the heat affected zone (HAZ), along a horizontal traverse which does not include any weld-bead overlap, as illustrated in the schematic drawing.

|

Martensite, HAZ

2.4 kJ/mm heat input. The photograph was taken at position 7 in the heat affected zone (HAZ), along a horizontal traverse which does not include any weld-bead overlap, as illustrated in the schematic drawing.

|

Martensite, HAZ

2.4 kJ/mm heat input. The photograph was taken at position 6 in the heat affected zone (HAZ), along a horizontal traverse which does not include any weld-bead overlap, as illustrated in the schematic drawing.

|

Martensite, HAZ

2.4 kJ/mm heat input. The photograph was taken at position 5 in the heat affected zone (HAZ), along a horizontal traverse which does not include any weld-bead overlap, as illustrated in the schematic drawing.

|

Martensite, HAZ

2.4 kJ/mm heat input. The photograph was taken at position 4 in the heat affected zone (HAZ), along a horizontal traverse which does not include any weld-bead overlap, as illustrated in the schematic drawing.

|

Martensite, HAZ

2.4 kJ/mm heat input. The photograph was taken at position 3 in the heat affected zone (HAZ), along a horizontal traverse which does not include any weld-bead overlap, as illustrated in the schematic drawing.

|

Martensite, HAZ

2.4 kJ/mm heat input. The photograph was taken at position 2 in the heat affected zone (HAZ), along a horizontal traverse which does not include any weld-bead overlap, as illustrated in the schematic drawing.

|

Martensite, HAZ

2.4 kJ/mm heat input. The photograph was taken at position 1 in the heat affected zone (HAZ), along a horizontal traverse which does not include any weld-bead overlap, as illustrated in the schematic drawing.

|

Martensite, fusion surface

2.4 kJ/mm heat input. The photograph was taken at position 2 at the fusion line, along a horizontal traverse which does not include any weld-bead overlap, as illustrated in the schematic drawing.

|

Martensite, fusion line

2.4 kJ/mm heat input. The photograph was taken at position 1 including the fusion line, along a horizontal traverse which does not include any weld-bead overlap, as illustrated in the schematic drawing.

|

Montage of weld

2.4 kJ/mm heat input. Montage with weld metal on the right and heat-affected zone on the left. The photographs are taken along a horizontal traverse which covers the 'recrystallised' region where weld-beads overlap, as illustrated in the schematic drawing. Higher magnification snapshots follow

|

Martensite, HAZ

2.4 kJ/mm heat input. Montage with weld metal on the right and heat-affected zone on the left. The photograph was taken at position 8 of the HAZ, along a horizontal traverse which covers the 'recrystallised' region where weld-beads overlap, as illustrated in the schematic drawing.

|

Martensite, HAZ

2.4 kJ/mm heat input. Montage with weld metal on the right and heat-affected zone on the left. The photograph was taken at position 7 of the HAZ, along a horizontal traverse which covers the 'recrystallised' region where weld-beads overlap, as illustrated in the schematic drawing.

|

Martensite, HAZ

2.4 kJ/mm heat input. Montage with weld metal on the right and heat-affected zone on the left. The photograph was taken at position 6 of the HAZ, along a horizontal traverse which covers the 'recrystallised' region where weld-beads overlap, as illustrated in the schematic drawing.

|

Martensite, HAZ

2.4 kJ/mm heat input. Montage with weld metal on the right and heat-affected zone on the left. The photograph was taken at position 5 of the HAZ, along a horizontal traverse which covers the 'recrystallised' region where weld-beads overlap, as illustrated in the schematic drawing.

|

Martensite, HAZ

2.4 kJ/mm heat input. Montage with weld metal on the right and heat-affected zone on the left. The photograph was taken at position 4 of the HAZ, along a horizontal traverse which covers the 'recrystallised' region where weld-beads overlap, as illustrated in the schematic drawing.

|

Martensite, weld metal

2.4 kJ/mm heat input. Montage with weld metal on the right and heat-affected zone on the left. The photograph was taken at position 3 of the weld metal, along a horizontal traverse which covers the 'recrystallised' region where weld-beads overlap, as illustrated in the schematic drawing.

|

Martensite, weld metal

2.4 kJ/mm heat input. Montage with weld metal on the right and heat-affected zone on the left. The photograph was taken at position 2 of the weld metal, along a horizontal traverse which covers the 'recrystallised' region where weld-beads overlap, as illustrated in the schematic drawing.

|

Martensite, weld metal

2.4 kJ/mm heat input. Montage with weld metal on the right and heat-affected zone on the left. The photograph was taken at position 1 of the weld metal, along a horizontal traverse which covers the 'recrystallised' region where weld-beads overlap, as illustrated in the schematic drawing.

|