Estimation of Type IV Cracking Tendency in Power Plant Steels

J. A. Francis, W. Mazur and H. K. D. H. Bhadeshia

Abstract

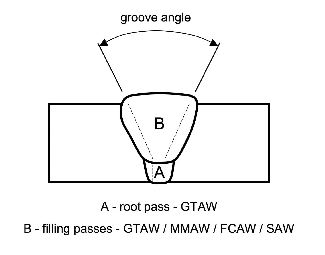

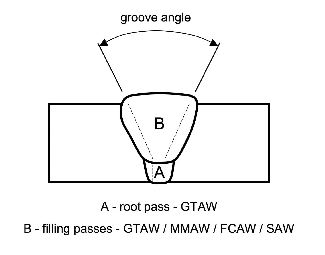

The cracking of welded joints is usually classified according to the position of the crack;

Type I and Type II modes occur within the weld metal, the former confined to the weld

metal whereas the latter may grow out of the weld into the plate; Type III cracking occurs

in the coarse grained region of the heat-affected zone. Type IV cracking is a feature of

welded joints in creep-resistant steels. It is associated with an enhanced rate of creep void

formation in the fine grained and intercritically annealed heat-affected zones of the weld,

leading to premature failure when compared with creep tests on the unwelded steel. These

zones contain coarse carbide particles, leading to a reduction in creep strength; the

particles also help nucleate voids. In a cross-weld test, the weakened Type IV region is

sandwiched between the stronger base plate and coarse-grained heat affected zone. The

resulting accumulation of creep damage in the Type IV region causes the premature failure.

Type IV cracking is prominent in the stronger 9-12 wt%

chromium steels. Since the problem arises from the heterogeneous

microstructure of the weld heat-affected zone, it can be

eliminated by a reaustenitisation and tempering heat treatment.

Unfortunately, this rarely is a practical option. Instead, components have to

be designed allowing for a reduction Δσ in the creep strength (or

equivalent reduction in creep life) due to Type IV cracking.

The magnitude of

Δσ is known to depend on the chemical composition, heat treatment

and the state of stress. It therefore has to be estimated experimentally for

each application. This clearly is a limiting factor in the design process,

whether it involves alloy development or welding. The purpose of the work

presented here was to develop a method which allows for the estimation of Type

IV limited creep rupture life, as a function of the steel composition and heat

treatment.

ISIJ International Vol. 44, 2004, pp. 1966-1968.

Download PDF file of paper.

Slide presentation.

Related Papers

Review on Type IV cracking in steel welds.

Quantitative Estimation of Type IV cracking Tendency.

Welding procedures and Type IV cracking.

Experiments on Welding procedures and Type IV cracking.

Design of Alloys for The Energy Industries

Photographs of Australia, where this work was carried out.

Tempered martensite Fe-9Cr-1Mo weld metal.

Type IV cracking study. Electrical heating blankets to maintain pre-heat temperature in the vicinity of the weld. |

Type IV cracking study - completed welds. |

Type IV cracking study. Preparation of weld. |

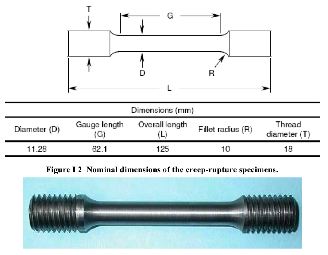

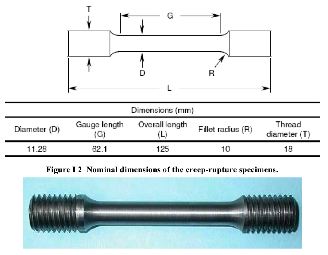

Type IV cracking study - the creep rupture test sample. |

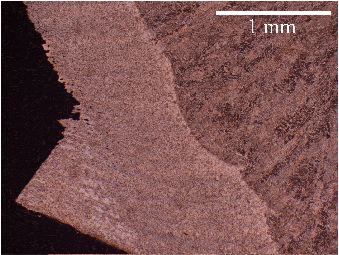

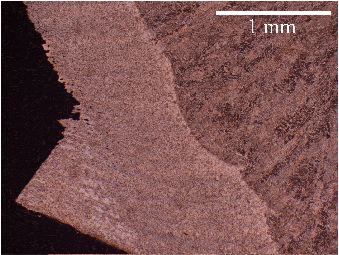

Type IV cracking study - typical rupture surface. |