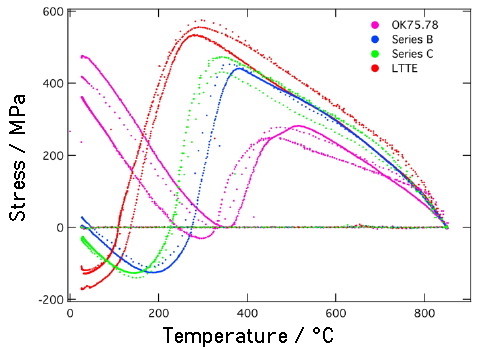

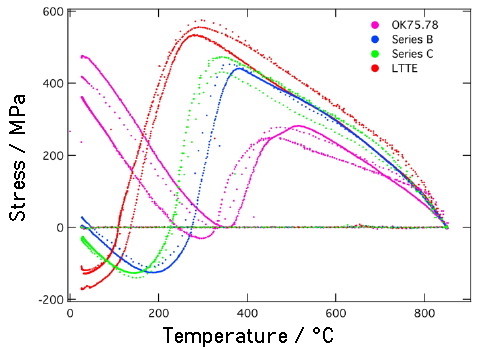

Residual stress in the vicinity of a weld can have a large influence on structural integrity. Here the extent to which the martensite-start temperature of the weld filler metal can be adjusted to mitigate residual stress distributions in ferritic steel welds has been investigated. Three single-pass groove welds were deposited by manual-metal-arc welding on 12mm thick steel plates using filler metals designed to have different martensite-start temperatures. Their residual stress distributions were then characterised by neutron diffraction. It was found that a lower transformation temperature leads to a potentially less harmful stress distribution in and near the fusion zone. The experimental method is reported and the results are interpreted in the context of designing better welding consumables.

Proceedings of PVP2007, ASME Pressure Vessels and Piping Division Conference, paper PVP2007-26544, San Antonio, Texas, 2007, pp. 949-956

Zipped archive of high-resolution images.

More about residual stress and its mitigation.

| Superalloys | Titanium | Bainite | Martensite | Widmanstätten ferrite |

| Cast iron | Welding | Allotriomorphic ferrite | Movies | Slides |

| Neural Networks | Creep | Mechanicallly Alloyed | Theses | Retained Austenite |

| PT Group Home | Materials Algorithms |