Alloying Concepts for Low Transformation Temperature Welding Consumables

L. Karlsson, L. Mraz, H. K. D. H. Bhadeshia and A. Shirzadi

Abstract

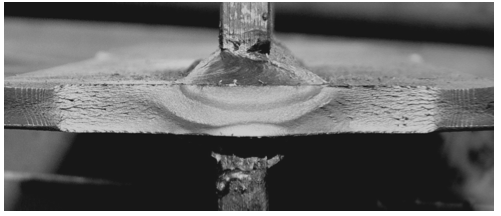

Fatigue cracks often initiate at welds as a consequence of large residual stresses and changes in geometry acting as stress concentrators. A concept showing promise in improving the fatigue life of welded components is the use of so called Low Transformation Temperature (LTT) welding consumables. These reduce the accumulation of residual stresses in welded joints by exploiting transformation plasticity to compensate for thermal contraction. This in turn enhances fatigue life. Three LTT alloys, based on different combinations of mainly Ni and Cr to produce low martensite- start (Ms) temperatures, have been studied. Fatigue testing showed similar results with a significant increase in fatigue strength for fillet and butt weld configurations for all three compositions. There was a pronounced interdependence between a lower transformation temperature, lower residual stresses and improved fatigue strength. The LTT effect was clearly related to the weld metal transformation temperature rather than the alloying concept per se. Dilution was an important factor in single-pass applications with Ms temperatures increasing by up to 70oC compared to the corresponding all-weld metals.

A 13Cr 6Ni alloy was identified as the most promising LTT-alloy considering not only fatigue performance but also aspects such as safety against hot and cold cracking, strength, toughness and ductility. This alloy is crack safe thanks to its ferritic solidification and as a bonus offers some corrosion resistance. Further optimisation is needed, though, to compensate for dilution effects in single-pass applications.

Biuletyn Instytutu Spawalnictwa, No. 5 (2010) 33-39

Download PDF file of paper

Related Papers

- "Crystallographic Texture of Stress-Affected Bainite"

Proceedings of The Royal Society A, 463 (2007) 2309-2328.

S. Kundu, K. Hase and H. K. D. H. Bhadeshia

- "Crystallography of Stress-Affected Martensite and Bainite"

Tata Search, 2 (2009) 226-232.

S. Kundu, K. Hase and H. K. D. H. Bhadeshia

- "Crystallographic Texture and Intervening Transformations"

Scripta Materialia 57 (2007) 869-872.

S. Kundu and H. K. D. H. Bhadeshia

- "Calculation of Crystallographic Texture due to Displacive Transformations"

International Journal of Materials Research, Vol. 99, 2008, 342-346.

H. K. D. H. Bhadeshia, H. Abreu and S. Kundu

- "Bainite Orientation in Plastically Deformed Austenite"

International Journal of Materials Research, Vol. 100, 2009, 40-45.

A. A. Shirzadi, H. Abreu, L. Pocock, D. Klobčar, P. J. Withers and H. K. D. H. Bhadeshia

-

"Transformation Texture in Deformed Stainless Steel"

Scripta Materialia, Vol. 55 (2006) 779--781.

S. Kundu and H. K. D. H. Bhadeshia

- "Crystallography of Widmanstätten austenite in

duplex stainless steel weld metal"

Science and Technology of Welding and Joining 14 (2009) 4-10.

J. W. Abtibol Menezes, H. Abreu, S. Kundu, H. K. D. H. Bhadeshia and

P. M. Kelly

- "Texture Analysis of Deformation Induced Martensite in a Stainless Steel: Microstructure and Microtexture Aspects"

Materials Research, 12 (2009) 291-297.

H. F. G. de Abreu, M. J. G. da Silva, L. F. G. Herculano and H. K. D. H. Bhadeshia

- "Crystallographic Texture of Induction-welded and Heat-treated Pipeline Steel"

Advanced Materials Research,89-91 (2009) 651-656.

P. Yan, Ö. E. Güngör, P. Thibaux and H. K. D. H. Bhadeshia

- "Induction welding and heat treatment of steel pipes: evolution of crystallographic texture detrimental to toughness"

Science and Technology of Welding and Joining, 15 (2010) 137-141.

P. Yan, Ö. E. Güngör, P. Thibaux and H. K. D. H. Bhadeshia

- "Investigations into the Microstructure-Toughness Relation in High-Frequency Induction-Welded Pipes"

8th International Pipeline Conference, 2010, published by the American Society of Mechanical Engineers, Alberta, Canada, IPC2010-31372, 1-9.

Ö. E. Güngör, P. Yan, P. Thibaux, M. Liebeherr, H. K. D. H. Bhadeshia and D. Quidort

- "Stainless steel weld metal designed to mitigate residual stresses"

Science and Technology of Welding and Joining 14 (2009) 559-565.

A. A. Shirzadi, H. K. D. H. Bhadeshia, L. Karlsson and P. J. Withers

- "Accumulation of stress in constrained assemblies: novel Satoh test configuration"

Science and Technology of Welding and Joining 15 (2010) 497-=-499.

A. A. Shirzadi and H. K. D. H. Bhadeshia

|

|