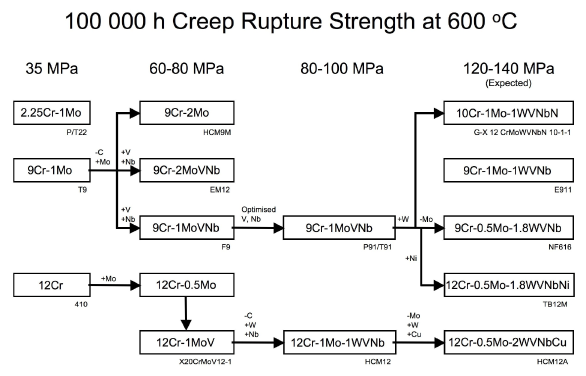

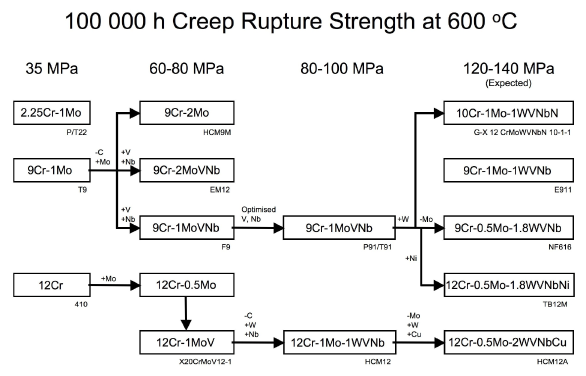

There have been concerted world-wide efforts to develop steels suitable for use in efficient fossil-fired power plants. Ferritic alloys containing between 9 and 12 wt % chromium are seen as the most promising materials in this respect, especially for thick-walled components such as headers and the main steam pipe in boilers. However, the performance of the improved steels has often not been realised in service, because premature failures occur in the heat-affected zone of welded joints in a phenomenon referred to as type IV cracking. This review assesses the relationship between the composition and microstructure of 9-12 Cr steels, the welding and fabrication procedures, and how these factors translate into a propensity for type IV failures.

Materials Science and Technology, 22 (2006) 1387--1395.

Quantitative Estimation of Type IV cracking Tendency.

Welding procedures and Type IV cracking.

Experiments on Welding procedures and Type IV cracking.

Design of Alloys for The Energy Industries

Photographs of Australia, where this work was carried out.

Tempered martensite Fe-9Cr-1Mo weld metal.

| Superalloys | Titanium | Bainite | Martensite | Widmanstätten ferrite |

| Cast iron | Welding | Allotriomorphic ferrite | Movies | Slides |

| Neural Networks | Creep | Mechanicallly Alloyed | Theses | Retained Austenite |

| PT Group Home | Materials Algorithms |

|

|